A quick recap to see how we got here:

- Barrel free-floated.

- Receiver bedded.

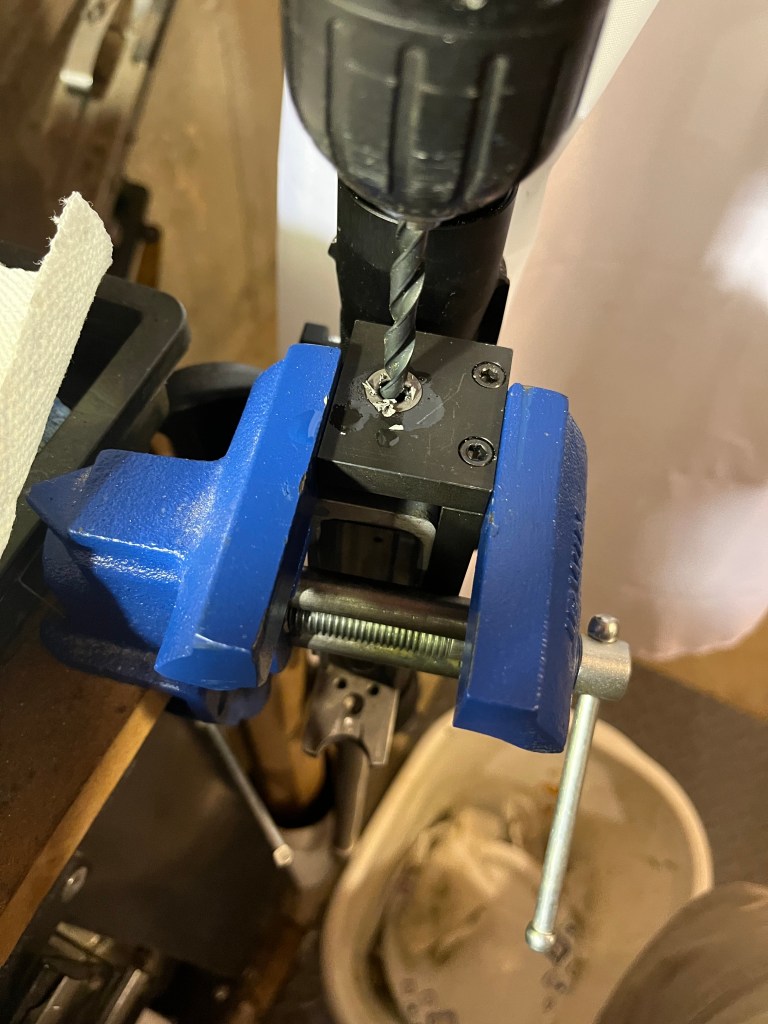

- Pillar and new escutcheon bedded in place.

- New trigger group installed.

- New action screw to receiver torque-tested.

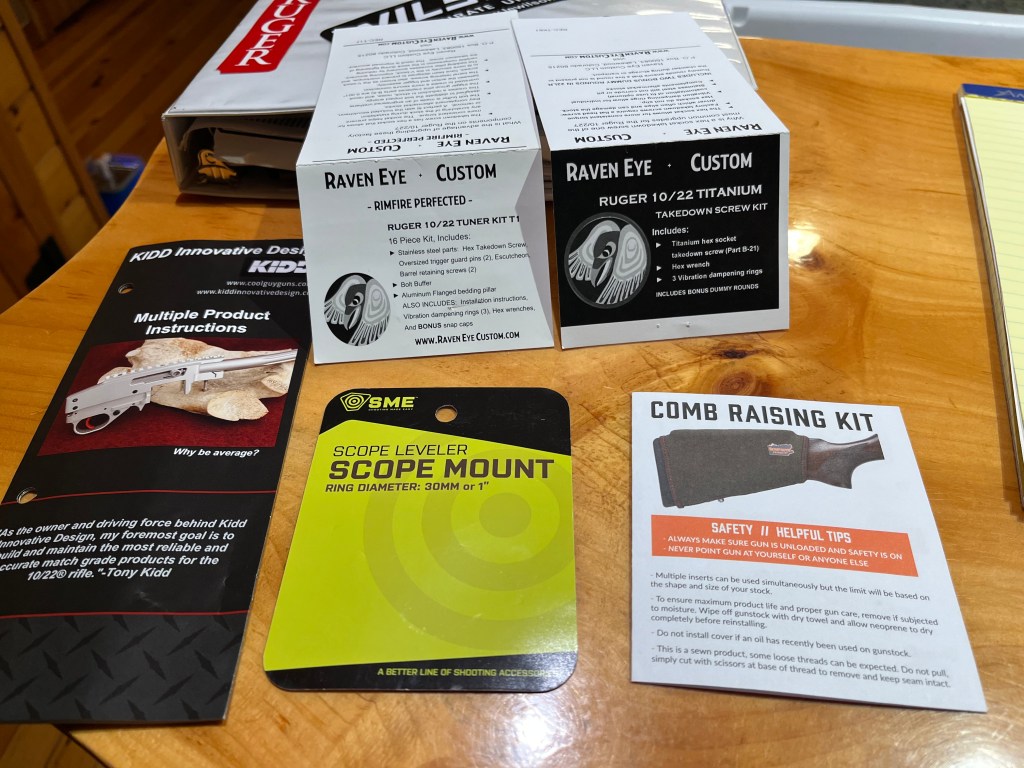

- Receiver tune-up parts installed.

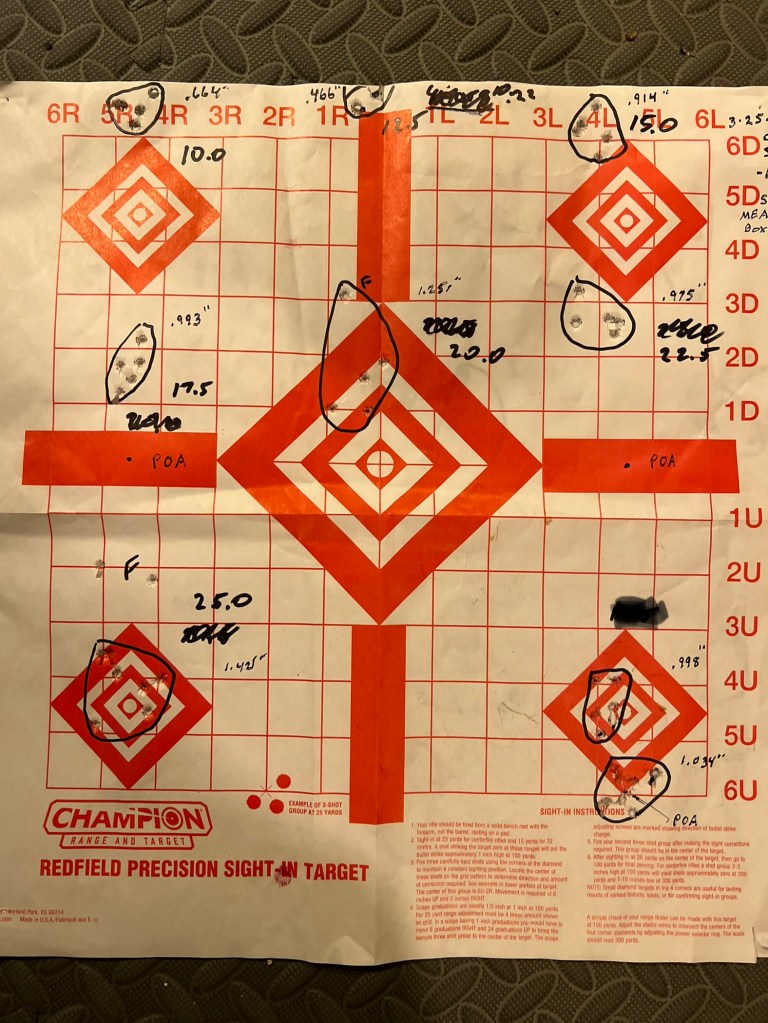

At this point I’ve put about $150.00 and many man-hours into the project. My initial conclusions were that I had increased accuracy somewhat, and that it was a fun project. But final testing after finding the proper torque on the pillar-bedded rifle showed a significant improvement – from over an inch at 50 yards to just over 1/2”. For a stock 20 year-old Walmart-purchased Ruger 10-22, I’ll take that.

However.

Before I had figured out the absolute criticality of torque on the action screw, I was getting such inconsistent results that I thought that I’d just order a new barrel. I also wanted to shoot suppressed; therefore it needed to be threaded. Off to Green Mountain.

Now, the original barrel is stainless, 21”. There is constant discussion about the perfect .22 barrel length – 16, 18, 22”? My Aspirin Shoot rifles are 16” and are under 1 MOA. I decided to try the Green Mountain stainless, threaded 16.25” bull barrel.

But to install it, we have to change our bedding.

Off to the range!

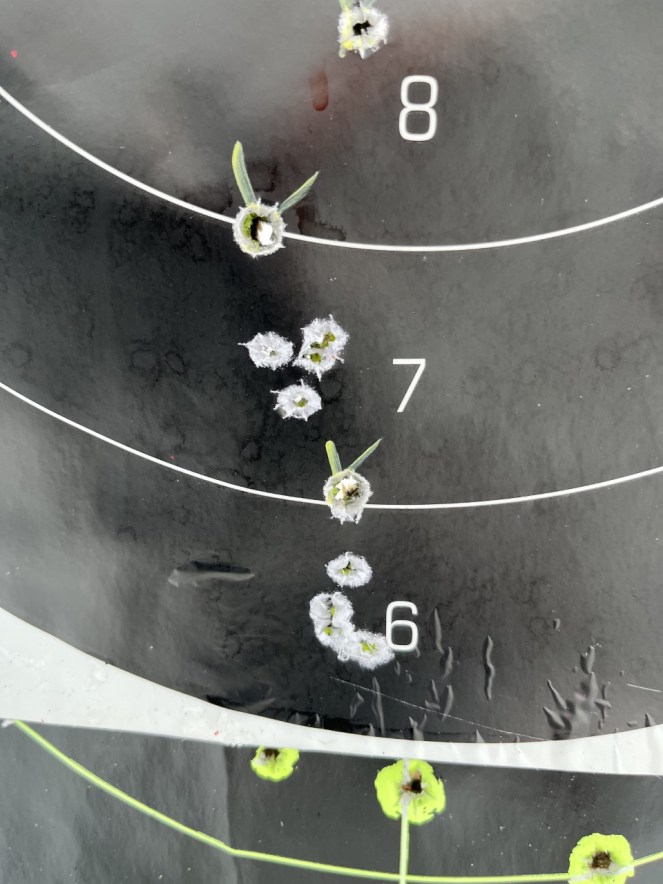

Sorry, the Dirty Bird targets don’t splash with .22. But unsuppressed we get groups of CCI Standard – .846, .544 1 F; Wolf – .457, .346 1 F; SK Rifle Match – .618, 1.00; and CCI Green Tag – .861, .744 1 F.

Suppressed is a little easier to see. We get CCI Standard at 1.126, 1.207 1 F (ouch!); Wolf – .343, .615 1F; SK – .658, .847; and CCI GT – .861, .645 1F.

Looks like my old standby, CCI Standard is out of the running, at least when suppressed? But all in all, the barrel seems to perform very well with some ammo and decently with other. My one regret is that the rifle no longer feeds Eley ammo. That stuff is superb in my Aspirin Shoot rifles. Unfortunately, it has a flat nose with a little cone in the center (patented!). The flat nose catches on the chamber edge and turtles.

And that’s the end of this story. 😇 Don’t worry. There’s more. Much more. Can you say “Aspirin Shoot”?