So how did she shoot after our first accurizing steps?

Terrible. All over the place. What gives?

As it turns out, torque on the action screw dramatically affects point of impact and group size. So, back to the range with my Wheeler Engineering FAT wrench.

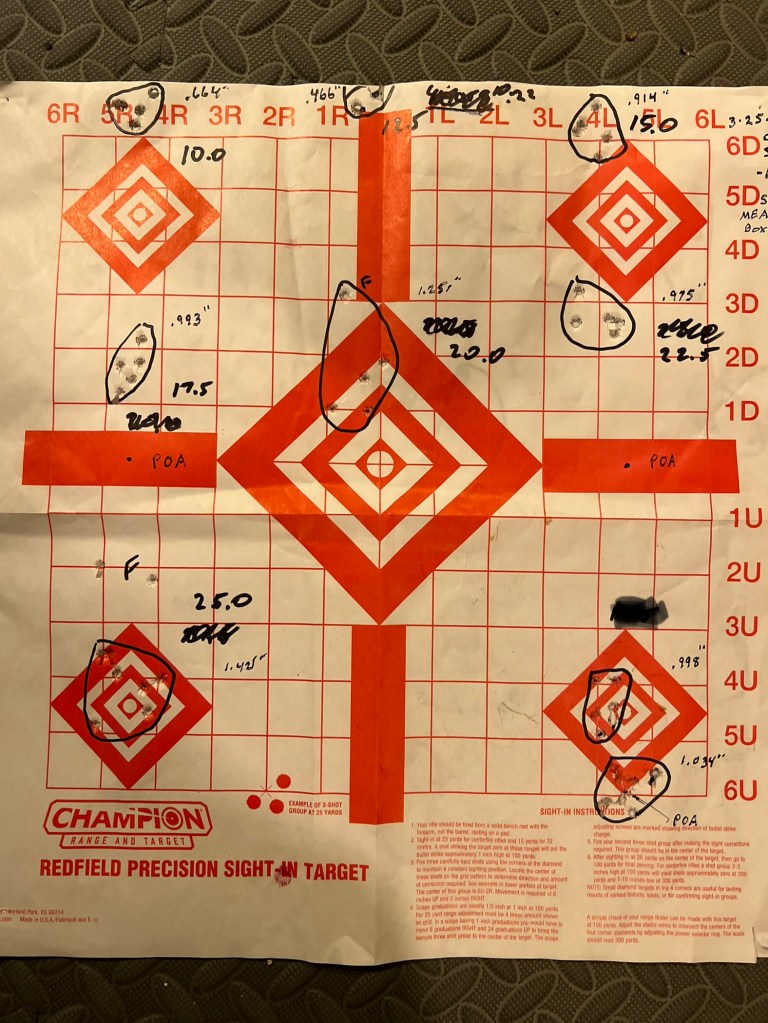

10 inch pounds to 25 inch pounds, and group size from .466” to 1.421”, a huge difference, but with accuracy nodes at about 13 inch pounds and 20-23 inch pounds.

So far, so good. On to pillar bedding (which i probably should have done first).

The pillar is sort of the shape of a flattened mushroom with a hole through it.The top surface of the pillar should sit at or slightly above the wood where the receiver normally rests, and the bottom goes through the stock to a new escutcheon. The pillar and escutcheon are glassed in place to become a permanent part of the stock. The new action screw now pulls the receiver down flush to the pillar – metal to metal so no compression of the wood in the stock.

First, scary cutting with drill press, levels, etc. Then Forstner drill bit cut. It fits! Glass in place.

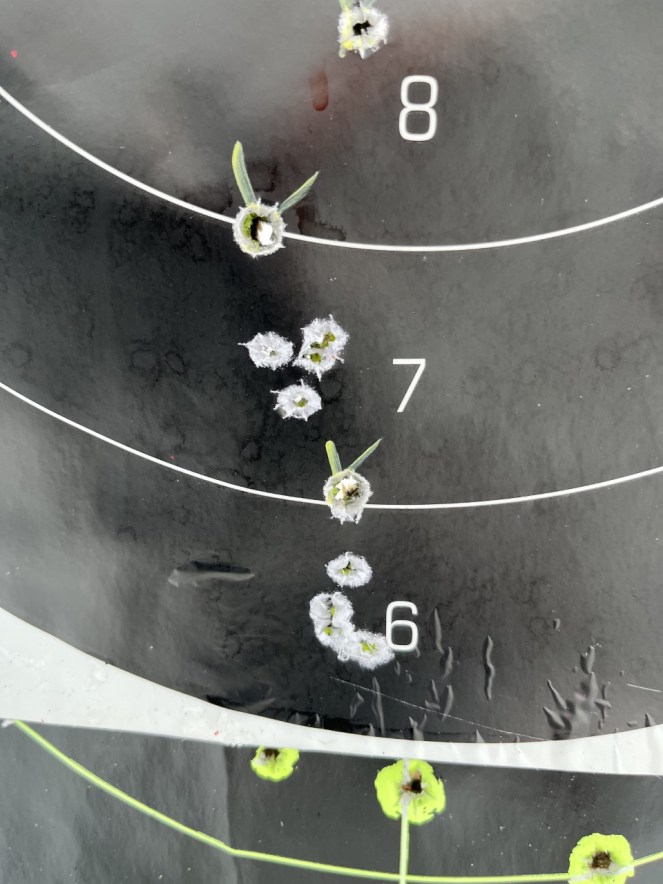

About 1/2” 5-shot groups at the nos. 7 and 6 with CCI Standard.

Yes, I’ll take it. But there’s more in Part3!